Based in Wichita Kansas, the Aerospace capital of the world, our manufacturing plant’s location is ideal for fast shipments worldwide. Our 15,000 square foot facility produces a wide range of shapes, profiles and rolled sections with Aerospace grade aluminum, stainless steel, and titanium alloys.

The Managing Director, Robert Smith, has 25 Years of direct Aerospace manufacturing experience with his apprenticeship through Boeing Wichita from machinist to working with the offload design team to management, specializing in Roll form and structural manufacturing. In addition to his extensive industry experience, he has also attended courses in Six-Sigma, Kaisan and other ‘Lean’ Manufacturing concepts.

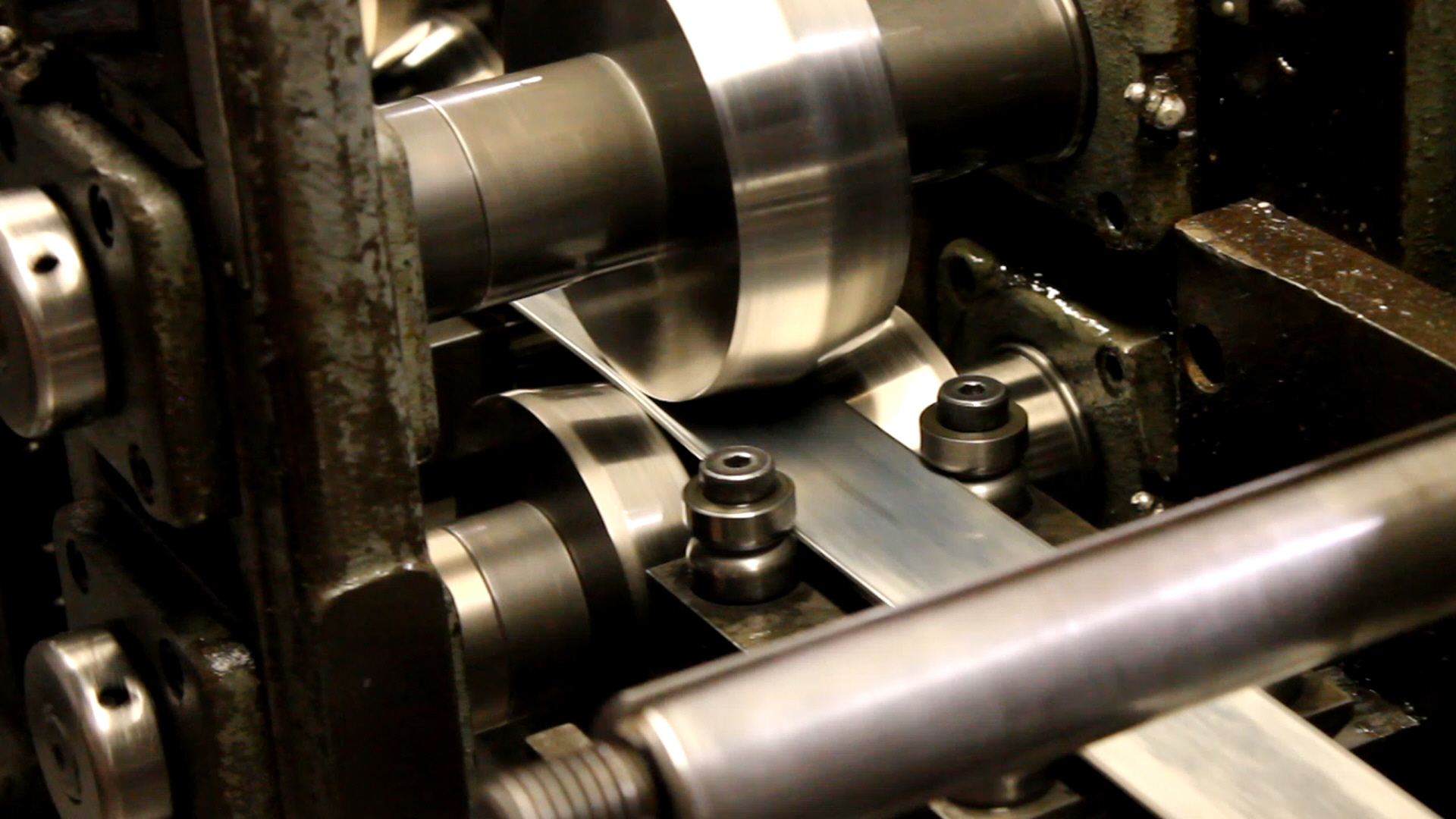

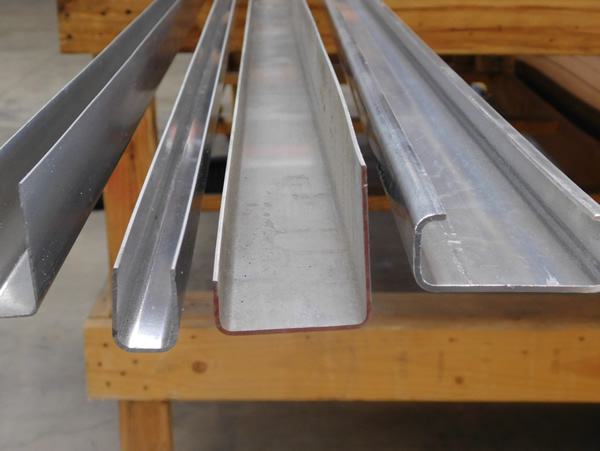

Our specialty is Roll Forming, a process in which coil or strip metal continuously passes through shaping rollers and dies to form the desired profile. We have the ability to manufacture roll form sections up to 75 feet in length with consistent tolerances as close as +/- 1 degree. Tooling is interchangeable and often times reduces manufacturing costs and lead time. All machining is closely monitored to ensure the highest manufacturing tolerances are maintained as per ISO requirements.

An ISO9001 and AS9100 approved manufacturer, AAA Air Support is dedicated to the supply of aerospace roll form shapes. With no minimum order we can produce as little as 12FT. Custom shapes are no problem, with in- house tooling design and manufacturing we can supply material to print at an affordable price. With a wide range of existing inventory in formed shapes available to ship next day in a variety of customer part numbers and alloys. Aerospace roll forms are critical when it comes to tolerance, and bend radius factors. AAA Air Support supplies material to BAC1480 standard tolerances unless specified. Our bend radius specification is BAC5300.

AAA Air Support can also accommodate a wide range of secondary processes including ultra sonic inspection and various coatings.